Services:0760-88209336

-

How to select and use elastic printing paste to ensure its color fastness?Time of issue : 2021- 11-12

How to select and use elastic printing paste to ensure its color fastness?Time of issue : 2021- 11-12If it is clothing, use water-based elastic glue paste. Because clothing printing requires no smell and soft hand feeling, especially for export clothing or high-grade products, especially strict printing

-

Precautions for the use of foaming paste printing materialsTime of issue : 2021- 11-12

Precautions for the use of foaming paste printing materialsTime of issue : 2021- 11-12It is suitable for weaving cotton fabric, knitted fabric, taping cotton, T-shirt and other garment printing. It has the characteristics of soft touch, strong tensile strength, and uniformity of three-dimensional polyurethane foam after the short term tempering process to maintain the growth of the pattern. For the big guys detailed introduction to the next polyurethane foam pulp instructions and common problems.

-

How to reduce the number of prints to improve efficiency when printing with gum paste?Time of issue : 2021- 11-12

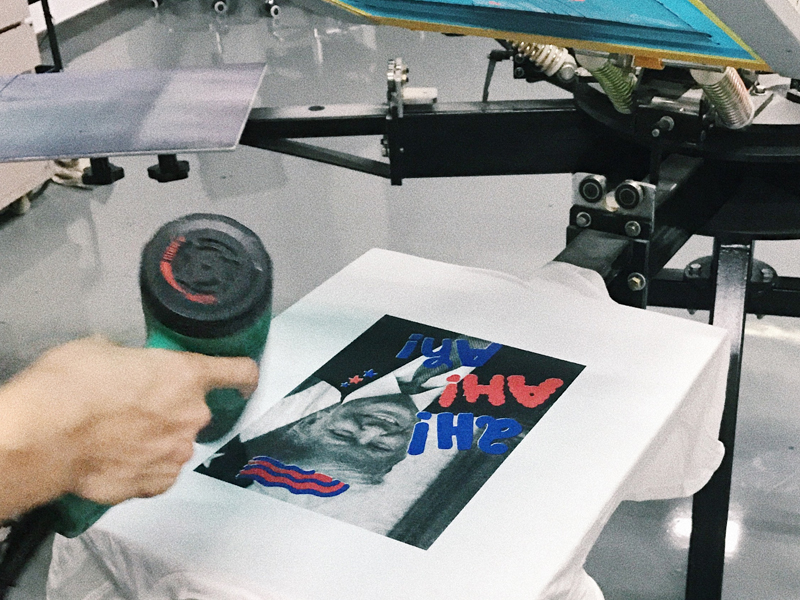

How to reduce the number of prints to improve efficiency when printing with gum paste?Time of issue : 2021- 11-12Glue paste printing, according to the characteristics of the fabric, ordinary cotton fabric generally need to print 3 times to achieve a better printing effect, especially some threaded cloth, sweatshirt cloth and other fabrics with deeper grain, that the number of printing is more than 3 times. In order to achieve the purpose of reducing the number of printing times and improving efficiency, we can add thick board pulp inside the glue pulp, or directly print with thick board pulp, which can achieve the effect of reducing the number of printing times. Sweatshirt fabric and other fabrics with deeper grain, 3 times can achieve the effect of printing flat and glossy.

-

Some small knowledge about the printing material process, do you understandTime of issue : 2021- 11-12

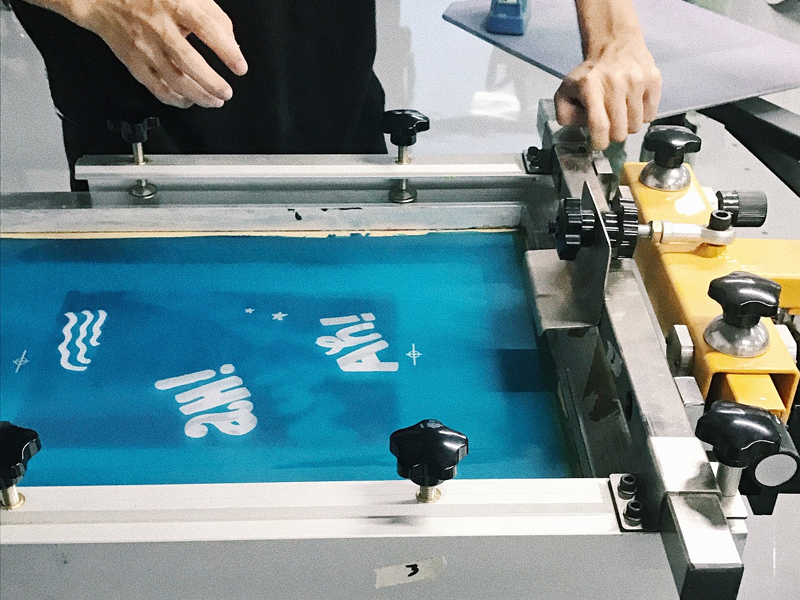

Some small knowledge about the printing material process, do you understandTime of issue : 2021- 11-12Screen method is to adjust the color of the screen to adjust the color of the picture, usually on the screen through the color menu to select or adjust the color. This approach is very useful when matching or starting to color, is a common method of color mixing designers

-

Application of high fastness nylon thick board pulp and water-based three-dimensional thick board pulpTime of issue : 2021- 11-12

Application of high fastness nylon thick board pulp and water-based three-dimensional thick board pulpTime of issue : 2021- 11-12This product is easy to operate, in order to ensure the printing effect, it is generally recommended to use a flat screen (ordinary screen) directly, without making a thick version; ordinary screen printing 1 mm high as long as the printing 6-8 times, the screen is surrounded by hard padding, the distance between the screen and the table is about 1-1.5 MM can be, in the use of thick screen printing, after the first printing needs to be dry before the second printing.

-

Perfect solution for poor fastness of thick board pulp garment printingTime of issue : 2021- 11-12

Perfect solution for poor fastness of thick board pulp garment printingTime of issue : 2021- 11-12The fabric may contain polyester components, or the fabric is smooth, and the thick board pulp for printing cotton is used instead of nylon thick board pulp. Use nylon thick board pulp need to add 1-1.5 curing agent

-

How to choose the use of elastic overprint paste to ensure its color fastnessTime of issue : 2020- 11-20

How to choose the use of elastic overprint paste to ensure its color fastnessTime of issue : 2020- 11-20If it is clothing class, choose water-based elastic overprinting adhesive paste. Because clothing printing requires no smell and soft hand feeling, especially for export clothing or high-grade product printing is especially strict...

-

About screen printing materials?Time of issue : 2020- 11-20

About screen printing materials?Time of issue : 2020- 11-20Silk screen: the uniformity of warp and weft, tensile strength, surface finish are higher than cotton screen, the disadvantage is that the elongation is too large, easy to age and deteriorate, the effect of light resistance is not good, long-term exposure to light is very easy to become brittle...

-

Color difference problem in screen printing?Time of issue : 2020- 11-20

Color difference problem in screen printing?Time of issue : 2020- 11-20Color difference The difference between the color of a pattern on the printed fabric and the color of a pattern on the printed fabric or the color of a pattern on the printed fabric is called color difference. Color difference is caused by the difference in hue, brightness, purity of the integrated results...

-

What is the problem of color transfer in screen printing?Time of issue : 2020- 11-20

What is the problem of color transfer in screen printing?Time of issue : 2020- 11-20The printing process produces serious "side dirt", so that the edge of the fabric or the edge of the fabric outside the printing table piled up more color paste, after printing the printing plate pattern and it meets or adjacent, color paste through the pattern mesh into the plate so that the color paste discoloration...

Contact Us

Address:Building1,Zone1,Shenzhong Science and Technology Park,Sixth Industrial Zone ,Nanlang Town ,Zhongshan City,Guangdong

Company Tel:+86-0760-88209336

Company Fax:+86-0760-88665833

Scan Inquiry

Scan and download enterprise brochures on WeChat